-

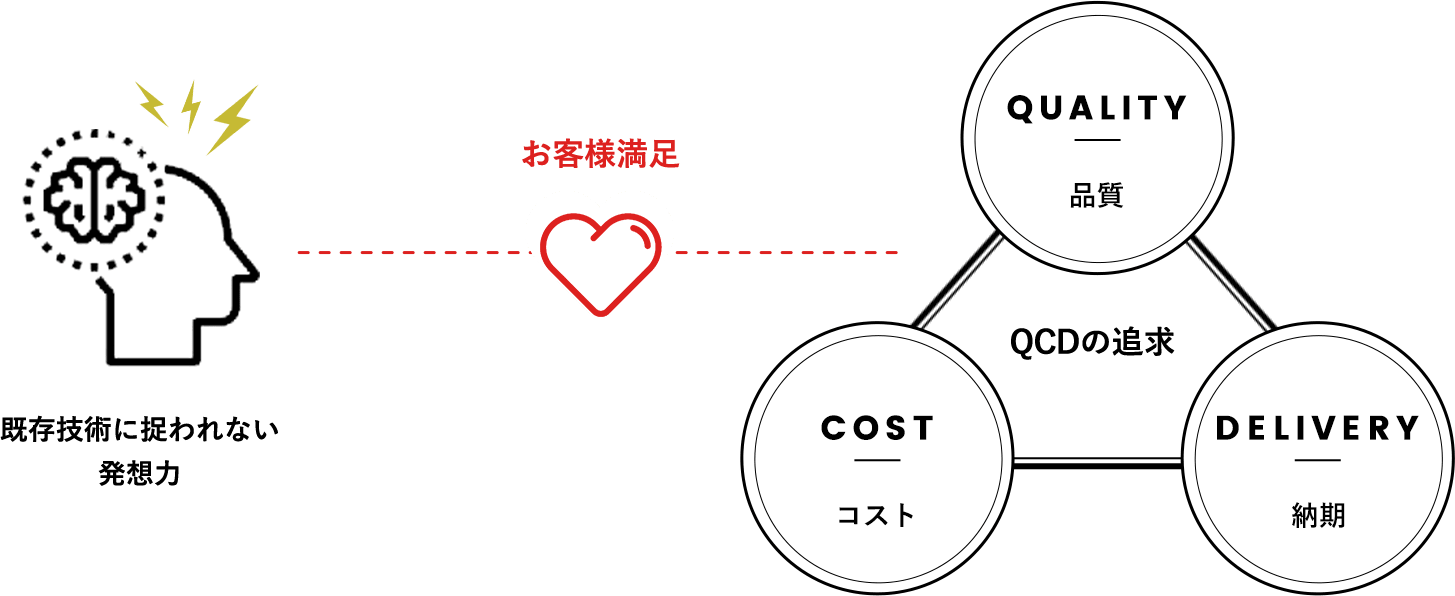

Flexible idea free from conventional technologies

-

Pursuing prices satisfied by customers

We were able to develop a new type of production that was not possible in the past through a change in thinking.

| Background |

There is a process to produce a compound material by laminating multiple materials. Okabe Mica produces mica tapes mainly by laminating film and glass cloth with mica. |

|---|---|

| Challenges |

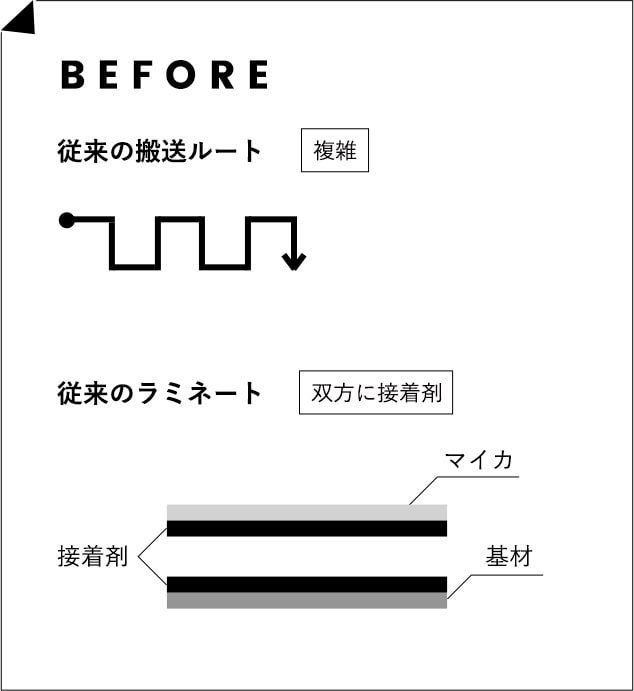

The following are the challenges related to producing tape with the base material requested by the customer:

(1) Because of its reduced strength, it wrinkles during the normal laminating process. (2) Gets longer when the base material is thermally processed after an adhesive is applied to it. In addition, although production could be performed by dividing the process into multiple steps, there was a problem that costs would increase. |

| Solutions |

Our conventional manufacturing method was to integrate adhesive-coated base materials to each of them.

The main reason was that the base material could not withstand the adhesive coating stress, so we switched to the idea of "production without applying adhesive." To solve these challenges, we optimized our manufacturing process as follows: (1) Optimization of conveying paths (2) Introduction of a thermal compression bonding method with optimization of laminating rolls After clearing the stated costs, we were able to realize results that satisfied the customer. |

| Conclusion |

Considering the best way to satisfy the customer’s needs first, we reviewed the manufacturing process.

|